Simac has a vast experience in building inspection systems for primary packaging components for the pharmaceutical industry. Glass vials are an important part of the total drug container solution. They should be free of defects and contamination in any stage of the production, fill or finish lines. To achieve and assure this level of quality, machine vision techniques can be used.

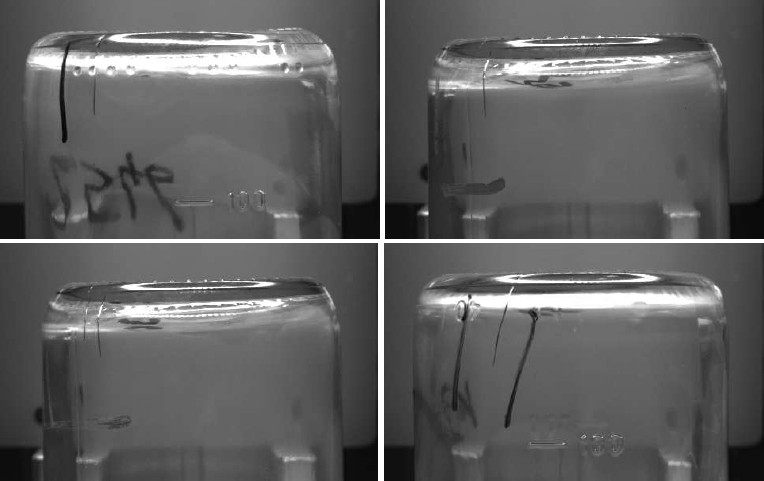

We build turn-key systems for inspecting vials on possible dimensional or cosmetic defects like cracks, airlines, scratches, dirt and inclusions. Geometry (diameter and height) of the total vial or parts like the body, brim, neck or lip can be measured and logged if needed. We typically use multiple cameras to capture in flight image data. The system in typically placed in-line and the results are saved per examined product, following defined production process standards.

We build turn-key systems for inspecting vials on possible dimensional or cosmetic defects like cracks, airlines, scratches, dirt and inclusions. Geometry (diameter and height) of the total vial or parts like the body, brim, neck or lip can be measured and logged if needed. We typically use multiple cameras to capture in flight image data. The system in typically placed in-line and the results are saved per examined product, following defined production process standards.

High speed 100% vision inspection can detect defects even when less visible and 100 um or smaller in size. High-end systems available can even detect invisible defects that are embedded in product itself or too small to see with the human eye.

Defects of 50x50 um in size and smaller can be accurately detected, depending on the size of the vial and the Field of View. Please contact us for an expert advice.

Our systems are designed, engineered and built in house according to GMP standards. As an alternative we integrate our machine vision expertise in existing product lines. This in case when space is limited or specific integration is required.

We are used to provide bespoke systems in all life sciences areas and typically our machines are installed in ISO-5 or ISO-7 cleanrooms.