The question was to create a fully automatic test and sorting machine. Working from bulk, every cup had to be separated and lined up for a quality inspection. These deep drawn molybdenum cups measure : diameter= Ø1.0mm, height= 3mm.

Inspection criteria:

Mechanical surface defects like holes, deformations, cracks, scratches and indents

Optical surface inspection on smoothness

12 cups/second

Correct cup (left) and defects; no bottom, indents & scratches

Bulk supply of micro cups

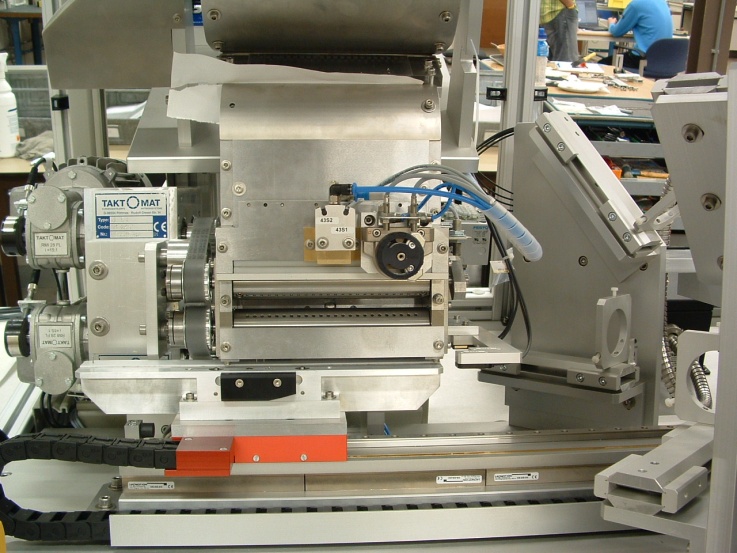

From bulk to single cups

From bulk to single cups

Line up of cups on the carrier

Cup carrier transport into the vision area

Cup carrier transport into the vision area

Eight cameras are used for one cup at the time

Eight cameras are used for one cup at the time

End station separation of the good & the bad cups (built in 2005)

End station separation of the good & the bad cups (built in 2005)