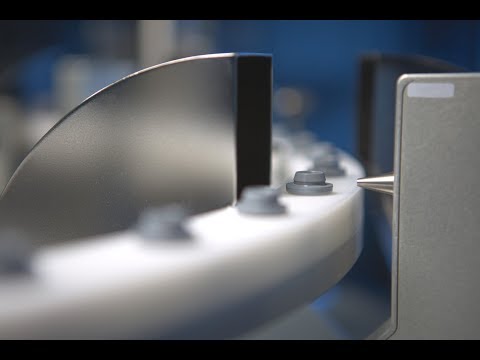

The rubber stopper machine vision inspection system Simac has developed is one of the world’s fastest inspection system for pharmaceutical rubber stoppers. This system is a result of more than 15 years development in high-speed automated vision inspection for high quality control within clean-room conditions.

The system features are:

- For coated and non-coated stoppers

- 13 stoppers / second

- Product diameter Ø12-35 mm

- For different color stoppers

- Inspection of top, bottom, outside and inside surface, stamping and shape faults

- Minimum detection of 50 µm square

A few examples of product faults:

Detection of moulded fiber on pharmaceutical stoppers

Detection of fibers on pharmaceutical stoppers

Spot detection on pharmaceutical stoppers

Metal inclusion pharmaceutical stoppers

Metal inclusion pharmaceutical stoppers

Metal speer and fibers

Metal speer and fibers

The continuous improvement of handling speed and improved detection systems resulted already in the 4th generation inspection machine solution.

Rubber stopper inspection machine development

Rubber stopper inspection machine development

Already more than 15 years ago Simac designed and built its first pharmaceutical rubber stopper inspection machine. Now, these 5th generation machines belong to the world fastest inspection systems for pharmaceutical rubber stoppers inspections.