Vision systems that detect color can be an important tool for detecting defects, detecting a mix-up of different batches of products, or verifying that the correct components are present in an assembly.

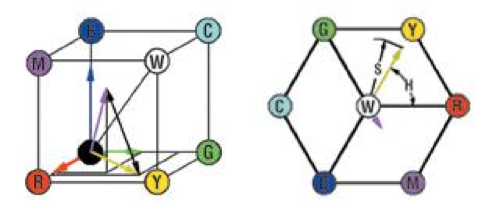

Most machine vision systems recognize color by representing image data in a three-dimensional “space.” In some systems (left), the three dimensions are red, green and blue. In others (right), the dimensions are hue, saturation and intensity.

Both analysis techniques can be inaccurate if lighting and other factors are less than ideal.

Certain defects on primary packaging parts are hard to see in black/white. E.g. brown spots on grey stoppers ask for color image processing. Also batch intermixing can be prevented by checking for color of the product.