In many industries the end product is packed in a sealed container to guarantee the quality and hygiene of the end product. To fulfill the specification shown on the container an airtight all-around perfect seal is needed. The production method for these of seals is that a heated mould disperses the heat in the glue what then binds the container and the top-sheet together.

In this seal-forming process there are many variables that influence the end result, for example; mould pressure, mould temperature, in-mould time, sheet- temperature, process speed, foil type, foil thickness, glue type, positioning of foil the on the container, full glue seam, and a glue seam without contamination.

Simac has great expertise in seal inspection for a wide variety of containers and end products.

Imagine the difficulties you will meet when, the container, the glue and the top-sheet are 100% transparent and the end product has to be packed under conserving gas.

If you would like to know if your product is properly sealed, just send in your container; our engineers can easily do a feasibility study determining what is possible.

combined seal and label inspection

normal image seal correct seal in 3d image leaking seal in 3d image

food seal proper seal image inclusions in seal

food seal correct defect seal

seal and top foil defect

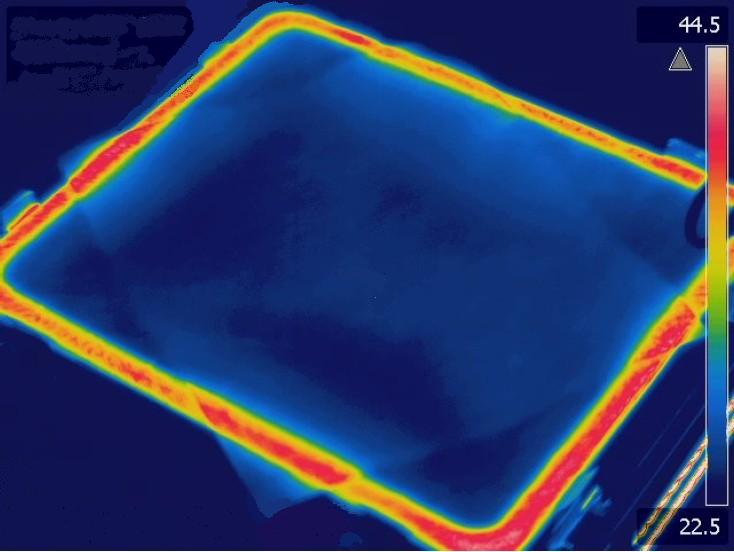

infrared seal inspection